Front forks are one of the most crucial parts of a dirt bike so you need to rebuild dirt bike forks on a regular basis. Rebuilding dirt bike forks includes cleaning and inspecting all internal suspension parts, replacing any worn out parts, and refilling the front forks with fresh fork oil.

Fork and oil seals pay a major role when it comes to how dirt bike forks perform. Fork seals on a dirt bike front forks prevent dust and debris from getting inside the fork legs and mixed into the fork oil. The fork leg has a dust seal and a separate oil seal working together to prevent oil leaks and oil contamination. The oil seals as well as the dust seals in dirt bike front forks will need regular cleaning and once worn out, a complete fork seal replacement.

Rebuilding dirt bike forks can drastically improve your suspension performance and fix slow, sluggish, or poor performing front forks. For that reason, it’s important to do a dirt bike fork rebuild even though it may sound like a big job. Actually, it is pretty straightforward and definitely well worth a half a days work.

In this post, we will discuss the following topics:

- What are fork seals on a dirt bike

- Dirt bike fork oil change and service intervals

- Rebuilding dirt bike forks – a step-by-step guide

- And lots more…

Next, we will explain how to rebuild dirt bike forks and how to change the fork oil. We will walk you through the main steps involved in the front fork oil service. You will also find out why you should service the forks and regularly clean the fork seals.

This post features affiliate links. If you use these links to buy something we may earn a commission at no additional cost to you. As an Amazon Affiliate we earn from qualifying purchases.

What Are Fork Seals on a Dirt Bike?

Fork seals on a dirt bike front forks are rubber seals that are located inside the fork legs. They act as a dust and dirt barrier between the internal suspension components and the fork oil.

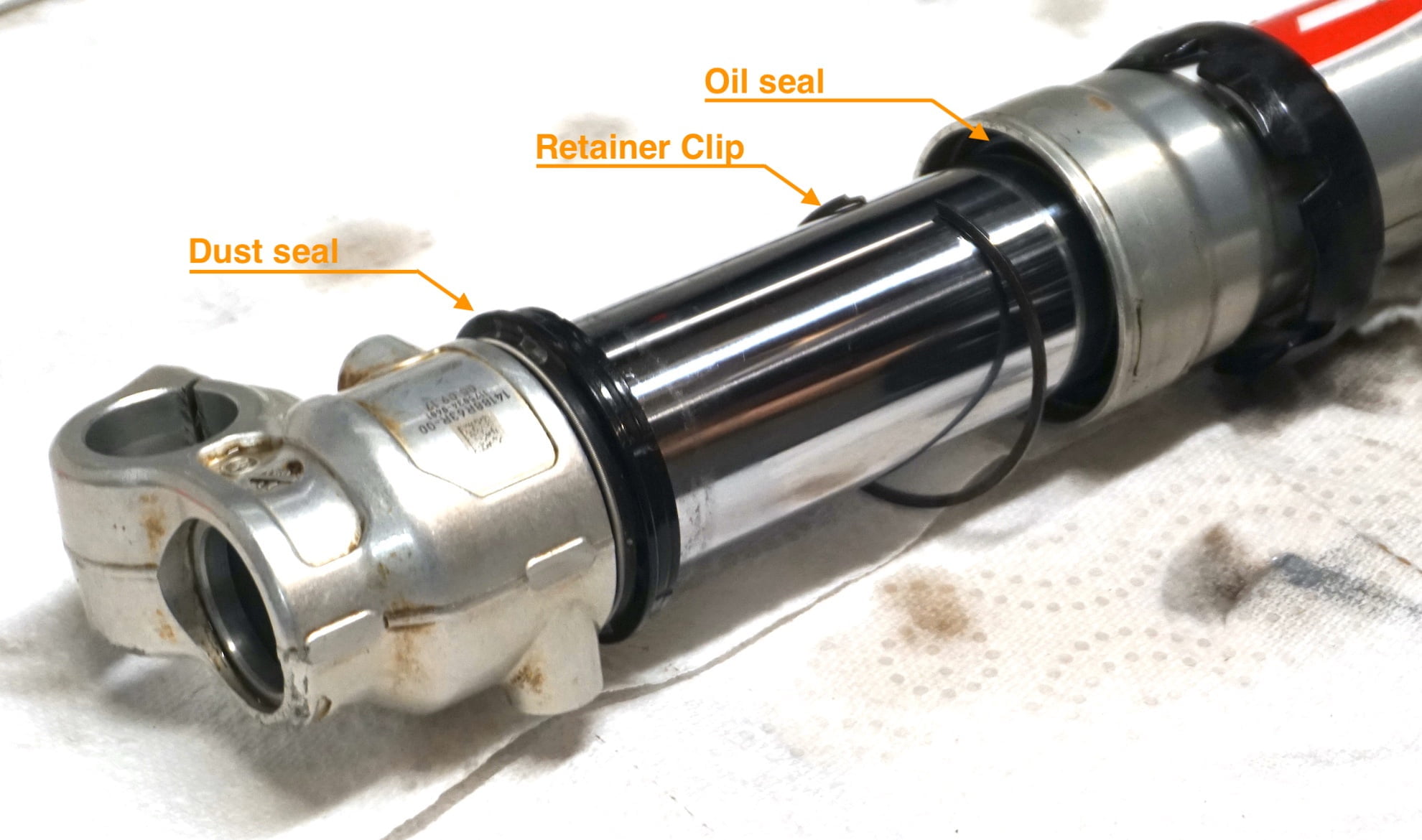

There are typically two fork seals in each of the front fork legs; the dust seal and the oil seal.

The dust seal in a dirt bike front fork acts like a wiper, wiping off any dust and dirt off the fork leg when the fork is compressed. This seal is typically visible and it’s the bottom one in inverted front forks.

Whereas the oil seal sits under or above the dust seal hidden from plain view. The oil seal is functioning as a barrier for the oil inside the fork leg and any oil that is spilled between the fork legs is wiped back into the oil chamber by the fork oil seal. If these oil seals are dirty or damaged, you can see leaking oil in the fork leg past the dust seal.

Dirt Bike Fork Oil Change and Service Intervals

The front suspension typically requires oil service every 20 to 40 hours depending on the dirt bike and riding conditions. The front forks have fork oil in the lower fork legs and they require a periodical dirt bike fork oil change or a complete rebuilding of dirt bike forks.

Rebuilding dirt bike forks includes inspecting the fork seals and bushings as well as inspecting any damaged internal parts. The suspension parts, such as bushings and seals, usually last longer than one oil service. So in general, the forks do not need to be rebuilt every time during a regular oil service.

If you ride in rivers, creeks, and in muddy conditions, you will likely need oil service more often compared to riding in dry conditions. Water, dust, and debris travel inside the main oil seals and dirty the oil faster. You can prevent this and fix leaky fork seals by cleaning the fork seals regularly. If the cleaning doesn’t solve the leaky fork seals, you are looking at a fork seal replacement.

You can use a seal mate or a similar fork seal cleaner tool or a fork seal doctor to clean the oil seal if you experience any leaks. We clean the seal after every few ride days and dirt bike washes.

When loading the dirt bike, you should use a fork saver to avoid putting pressure onto the fork seals when strapping the dirt bike down. Another good addition is to use quick release fork bleeders to release any excessive air pressure inside the fork legs to avoid leaking fork seals.

Typical dirt bike forks, like the WP Xplor and similar forks (used by KTM and Husqvarna), you can usually start noticing performance issues around 30 to 40 hours. And above 40 hours, the forks typically will have a noticeable slowness as the oil gets more and more dirty.

A suspension, rear shock, and fork rebuild done by a third party service company can set you back anywhere from $400 and up per service. A front fork seal replacement alone with oil service sets you back around $200 at the minimum.

Learning how to perform a regular front fork oil service or completely rebuilding the dirt bike forks is a great way to save money. You will also be able to get back to riding immediately and you don’t need to wait for the service to be completed.

Read also: How to clean leaking fork seals on a dirt bike

Rebuilding Dirt Bike Forks

Let’s start with covering the recommended tools and how to prepare the dirt bike and get things ready for rebuilding dirt bike forks and inspecting fork seals.

Fork oil service will take about 2 to 4 hours to complete. You do need some special tools, but you save money even on the first service.

These instructions are specific for the 2018 KTM 300 XC-W that uses XPlor 48mm front forks. This said, these are very common type front forks that KTM and Husqvarna use. And for other models, this works as a great guide to understand the level of work and steps required to service the front forks.

A Typical Front Fork DIY Service Length

Dirt bike fork seal replacement takes about 3 hours total. This is because you will need to separate the fork legs to access and replace the old seals.

Fork oil change or fork oil service only is slightly more straight forward but really takes the same time. Some riders choose to change the fork oil without breaking the legs apart, which in our opinion leaves a lot of the old oil and dirt inside the fork legs. We recommend doing it correctly each time and spend the extra hour or two to make sure parts are clean and inspected.

Recommended Tools for Rebuilding Dirt Bike Forks

While each dirt bike will require specific tools, all modern dirt bikes have very similar designs on the forks. So, the following tools apply to most fork oil services. Check the specific tool sizes your dirt bike is using.

The oil service is a fairly simple process but a few special tools will make it smoother and safe. In addition to new fork oil and possibly new seals, these are the typical tools you will need for changing the fork oil:

- Seal bullet (the orange plastic cone)

- Seal driver (the brass colored metal parts)

- Fork cap tool (the blue wrench)

- Hex male socket (17mm) for opening the lower fork cap

- Picks or small screw drivers to help pull seals and clips

- 4W fork oil (check your service manual for correct oil weight)

- New fork seals

- Oil pan

- Oil measuring cup

- Heat gun or blow torch

- Service manual for checking the needed fork oil quantity

- Oil level gauge

- Suspension cleaner

- Torque wrench

1. Prepare the Dirt Bike for the Fork Rebuild

Start by washing the dirt bike well and setting it on a center stand.

Position the dirt bike so that the front tire is not touching the ground. You can set a wrench under the front of the skid plate to lift the front tire slightly off the ground.

Next, prepare a good stable and clean tabletop or a similar place where you can lay down all parts and tools. Prep the table with disposable cloths or cardboard and paper. Cleaning the forks can get messy.

2. Remove the Front Wheel

Start with loosening the front wheel axle crimp bolts and removing the front axle. Slide the wheel off the dirt bike. Next, remove the front brake caliber from the left fork leg.

3. Remove Both Fork Legs and Clean Them Well

First, remove the upper and lower triple tree bolts. After you open the bolts, rotate each fork leg so that they slide down easily without damaging or scratching the upper fork leg.

Twisting the fork towards the fender on each side will loosen the triple tree clamps and allow the fork legs to slide down without resistance.

Once you get the fork legs out of the triple trees, clean them again properly. You don’t want any debris or sand get into your clean service area and inside the forks to ruin the fresh fork oil.

You can use compressed air and a brush to clean the forks. Also clean the triple trees properly. Clean any dirt in the clamps and inside the triple tree housings.

Important: For both fork legs, count and write down the current clicker setup. It’s important to close both clickers completely (turn clockwise until stopped). This will ensure that you won’t have any issues while reassembling.

4. Begin the Front Fork Leg Disassembly

After you have cleaned and prepped the dirt bike front fork legs, start the fork leg disassembly so that you can service the forks and change the fork oil and inspect fork seals.

We usually focus on one leg at a time to avoid mismatching any parts.

5. Remove the Upper Fork Cap

Start by opening the fork cap. You may need to use a soft jaw vice or a bench to hold the fork leg in place. You can also loosen the cap when the legs are still on the dirt bike if you don’t have a soft jaw vice. Be careful not to damage the upper fork legs.

Next, slide the upper fork leg down to reveal the spring. Use an adjustable or fixed wrench to hold the nut inside the spring to break the cap loose from the suspension internal parts. To do this, push the spring down so that you can put the wrench in place and loosen the cap.

Once the fork cap is loose, set it aside.

Next, remove the spring and possible spacers under the spring as well as the adjuster rod (the long push rod inside the center piece). Set the parts on the table for cleaning. Pour out the old fork oil into an oil pan.

6. Remove the Lower Fork Cap

Next, open the bottom fork cap. Again, you can use a vice to grip the lower fork leg.

Put the oil pan under the vice to catch any dripping fork oil.

Rotate the fork leg so that you can access and twist the hex cap open.

Once you open the lower cap, more fork oil will pour out. Set the lower fork cap aside for further cleaning.

7. Remove the Dust Seal or Wiper and the Retainer Clip

Start by removing the dust seal or the wiper.

Wedge a small flathead screwdriver between the fork leg and the fork seal. Carefully push the fork seal outward by wiggling and twisting the screwdriver to drive the fork seal out. Do not strip the rubber fork seal. Sometimes a dull knife works well.

Next, remove the retainer clip. This clip holds the actual oil seal underneath it and it also acts as a stopper for the fork legs preventing them from separating. Use a pick to remove the clip and slide it down on the fork leg. Also remove the fork leg spacer that pushes the oil seal on top of the area that needs to be heated next.

8. Separate the Fork Leg Upper and Lower Sections

Next, separate the lower and upper fork legs to inspect the fork seals and perform a final cleaning of all parts. Do not forget to remove the plastic fork leg spacer that sits over the oil seal before applying heat.

Start by heating the oil seal area with a heat gun or a blow torch.

Make sure to only heat the oil seal area about an inch on the beginning of the upper fork leg and not the dust seal or the spacer. Heat evenly until slightly too hot to touch.

To separate the fork legs, grab both the lower and the upper fork legs firmly. Hold the forks level in front of you, on the chest level. With one motion, quickly pull both fork legs apart. You may need to do this few times before the oil seal comes loose.

Sometimes the oil seal is stuck and it might be difficult to break the legs apart. It can feel as if something is holding it in place. If you have removed the retainer clip and heated the fork leg properly, use the entire length of the fork to get some momentum and pull them apart. They will break loose eventually.

Once you have successfully taken the fork legs apart, place each part on the clean table top for cleaning in the order you took them out from the lower fork leg.

9. Clean the Front Fork Internal Parts With Suspension Cleaner

Clean all parts with suspension cleaner solution and paper towels. Do not use brake cleaner as it eats the rubber fork seals.

10. Inspect the Fork Seals and Bushings for Wear and Tear

Inspect the fork seals for scrapes or cuts and anything that may indicate worn out seals. It is not necessary to change the dust or oil seals every time you change the fork oil. They usually last 2 to 4 oil changes if cleaned frequently. Seal sets are usually relatively cheap and last anywhere from 100 to 200 hours with proper care.

Next, inspect the upper fork leg bushings for wear and tear. The fork leg has a larger, wider bushing that wears out on the inside and one smaller bushing that is wearing from the outer side. Check each bushing and if you see any scrapes discoloration in the surface material, replace the bushing. Worn out bushings increase friction when the parts are moving inside the fork legs.

How to Replace Fork Seals on a Dirt Bike

A fork seal replacement is very easy to carry out while rebuilding the dirt bike forks. When you pull apart the parts for cleaning, inspect and identify any worn out seals and replace them with new ones.

If you plan to perform a fork oil service only and have no prior issues with leaks, usually you can reuse the old seals and clean them regularly with a seal mate or a seal doctor to prevent any dust from entering the fork seals.

Fork Seal Replacement Cost

When properly cleaned, the seals will last a long time without replacing. A typical fork seal replacement cost is about $50 to $100 with a new wiper (dust seal) and an oil seal for dirt bikes. You can also find affordable fork seal and bushing kits for rebuilding the forks.

Below is an example fork oil seal and wiper (dust seal) for many common 48mm WP forks. You need to buy two sets, one for each fork leg.

We can recommend SKF fork seals as they seem to run very long without issues. They are also the same seals that KTM and Husqvarna and others use in the WP forks from the factory.

SKF fork seals – Check the price and specific parts on Amazon.com

Pivot Works is another favorite brand we can recommend. They offer complete front fork rebuild kits with fork seals and bushings for a great price. They also advertise lifetime replacement guarantee.

Pivot Works fork seals and rebuild kits – Check the price and fitment on Amazon.com

All Balls fork seals are also high-quality products. The brand also makes complete front fork rebuild kits with seals and bushings.

All Balls fork seals and rebuild kits – Check the price and parts availability on Amazon.com

11. Start the Front Fork Reassembly

Now that the internal parts are clean and worn out parts are replaced, it’s time to start putting things back together and complete rebuilding the dirt bike forks.

12. Reinstall the Fork Oil Seal, Dust Seal, Bushings, and Retainer Clip

Push the seal bullet in place. If you don’t have a seal bullet, wrap a piece of tape around the sharp edges on the lower fork leg to prevent any seal damage.

Use suspension grease or fresh fork oil to lubricate all seals before the assembly. Lube the outside of the oil seal slightly for easier installation and removal. This helps to make sure the seal won’t stick into the fork leg housing.

Slide the dust seal, the retainer clip, the oil seal, the retainer ring, the smaller lower bushing, and finally the larger bushing in place. Pay attention to the assembly order.

Make sure you have greased the oil seal also on the outside and slide the upper fork leg in place.

Wrap the seal driver around the fork leg and push the oil seal in its place with the seal driver.

When installing the oil seal, make sure it sits fully in its place and the retainer clip groove is fully visible.

Next, reinstall the dust seal and the fork mudguard spacer in place.

13. Reinstall the Fork Damping or Rebound Rod

Next, reinstall the damping or rebounding rod in place. Grab the rod and the lower cap and align them inside the lower fork leg.

Use your index finger to realign the rod inside the fork leg. Lube the o-ring in the bottom cap and secure it in place by hand. Use a torque wrench to finish tightening the lower cap in place. Your service manual will tell the correct torque setting.

14. Add Fork Oil and Bleed Air Out of the Forks

Check your service manual for the correct oil quantity and correct fork oil weight.

Fork Oil Quantity and Fork Oil Weight

Forks typically take around 600 to 650ml of light 4W oil for each fork leg (like in KTMs and Husqvarna WP inverted forks).

If you cannot find the correct amount, search for the oil height. If you cannot find any information to your forks, go by the recommended oil level of 110mm measured from the top of the fork leg to the oil level. You can use the oil level measurement tool or a clean wooden stick to set the oil level correctly.

KTM recommends using 4W oil, but you can use thicker 5W fork oil also in a bind. The lower the fork oil weight, the less resistance and faster the fork is able to move in the operating temperature. If you add higher fork oil weight, for example 10W, you will notice a considerable slowness in the forks, which can be adjusted using the clicker settings. You can use the different fork oil weight to fine-tune the suspension performance to your liking. Otherwise, stick with the fork oil weight the manufacturer recommends.

There are few tricks to how to set the oil correctly and remove any air trapped inside the suspension components.

In our forks, we measured 635ml of Motorex 4W fork oil for each fork leg and measure the oil level after filing for accuracy.

Start by adding about 75% of the total oil quantity. Carefully pour the oil in and make sure the inner push rod hole does not get any oil in it. It is the clicker adjuster rod and it should never have any oil inside it.

After adding the first set of oil, move the fork push rod up and down a few times to push the oil further inside the fork. Add rest of the oil (25% of the total oil quantity) slowly moving the push rod up and down.

In addition to the total oil quantity, the service manual also tells you the oil level measured from the top of the fork leg. This is usually around 110mm from the top.

It’s important to note that if you use this oil level measurement method, you need to make sure to properly bleed all air out of the fork first for accurate oil level measurement.

15. Reinstall the Spring and the Fork Cap

Finally, it is time to install the spring and the fork cap back in place.

Installing the spring is simple. Just remember to check if the fork has any plastic spacers and install any spacers first. Many KTM WP forks have a plastic spacer on the bottom side of the spring.

Once the spring is in place, insert the adjuster rod inside the center of the suspension rod.

Make sure you have threaded the rotating push rod down on the threads, so that the fork cap will completely seat inside the clicker housing. The threads need to seat first into the cap clicker and then on the cap larger diameter. An incorrect installation will prevent clickers from working properly and will rotate endlessly.

After the final assembly, rotate the clickers to all open and then all closed. Then set the clickers to previous settings you wrote down at the beginning of the fork service or to the service manual’s recommended setting.

Note: If the clicker keeps rotating and doesn’t seem to stop on either end, it means that the push rod threads are not in place with the clicker threads. This can happen if the push rod threads are not fully threaded in where it shows most of the threads on the top.

Naturally repeat the fork oil service for the other fork leg. Steps are identical for both fork legs.

16. Reinstall the Front Forks Back on the Dirt Bike

Once you have changed the fork oil to both fork legs, the last thing to do to complete the rebuilding of the dirt bike forks is to install the forks back on the dirt bike.

You can find detailed instructions on how to correctly install and tighten front forks in our article how to align dirt bike forks. Here is a quick summary:

- To install front forks back to the dirt bike, start by sliding the forks back to the triple trees. Rotate the fork leg while you slide them to the desired height and make sure the air bleed screws are facing forward.

- Next, tighten the top triple tree bolts slightly to hold the forks in place.

- Install the front tire and brake caliber in place. Torque the axle bolt. Do not tighten the crimp bolts yet.

- Next, torque in the top triple tree bolts.

- Rotate the front tire and apply the front brake quickly to center the wheel on the axle.

- Then take the dirt bike off the center stand and while holding the front brake, rock the dirt bike forward to push the forks in. This will help center the front end and release any tension.

- Place the dirt bike on the center stand and torque the axle crimp bolts.

- Torque the lower triple tree bolts.

- Finish the fork service by installing any remaining plastics or other parts.

In Conclusion

Rebuilding dirt bike forks can sound intimidating or difficult. But like anything else, with great instructions and some practice it actually is quite easy.

Servicing front forks can really help keep costs down and make the dirt bike feel plush and performing like new. We highly recommend learning how to change fork oil and service your own dirt bike front forks.

Keep them plush!

Read next: